This relief printing technique enables direct transfer of ink print from the lifted printing elements onto flexible printing materials. It is ideal for printing primary and secondary packaging, self-adhesive labels and monofilms.

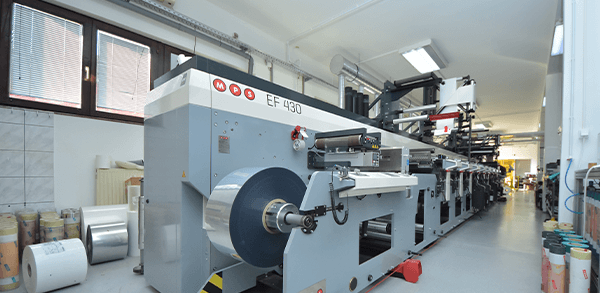

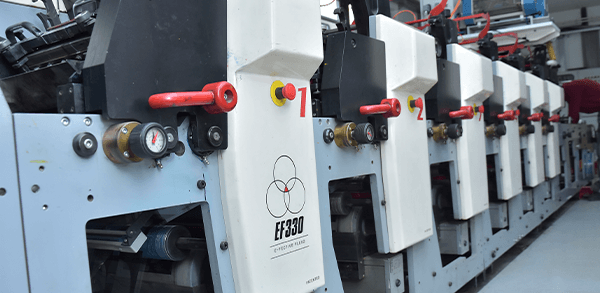

Given that this technique of direct printing is currently going through the largest technological expansion, and given its importance to the graphic industry, Grafomed has included flexo printing in its services back in 2009. Since the introduction of this service, Grafomed has relied on the most contemporary equipment in the printing technology, which is why in 2019 we acquired and set in motion another flexo print machine, of the latest generation.

It is flexo printing that makes up more than 80% of our business today.

Our expert team works with the most modern equipment and UV ink, and, owing to the quality, the speed and the reliability of flexo print, as well as the latest technology, we are capable of responding to the needs of various industries, such as the pharmaceutical industry, cosmetic industry, industry of energetics, industry of oil and lubricants, food industry, fruit and vegetable industry, industry of alcoholic and non-alcoholic beverages, and other.

Flexo print guarantees a swift and efficient result, with the possibility of processing a wide range of materials, including self-adhesive polypropylene, PVC, polyethylene, paper, WAL films, shrink sleeve and special paper for wine bottle labels.

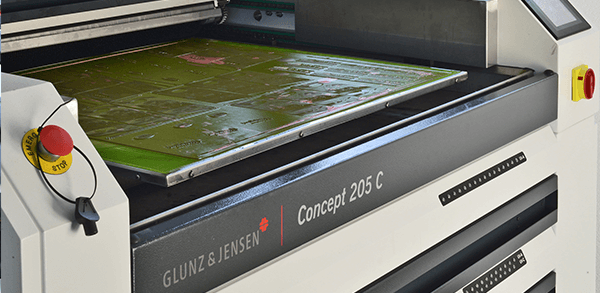

Our equipment is composed of the latest generation of machines and guarantees precision, clarity and efficiency in printing. We offer the possibility of developing photo-polymerous plates necessary for high-speed printing as a response to short deadlines set by clients. For us, the speed of working does not result in the reduction of quality, but in additional productivity.

We execute printing of all kinds of labels on various materials for the needs of different industries.

Self-adhesive labels

(paper, special wine bottle paper, polyethylene, polypropylene)

Wrap-around labels

(WAL) on BOPP materials of different micronage (minimum 12 microns)

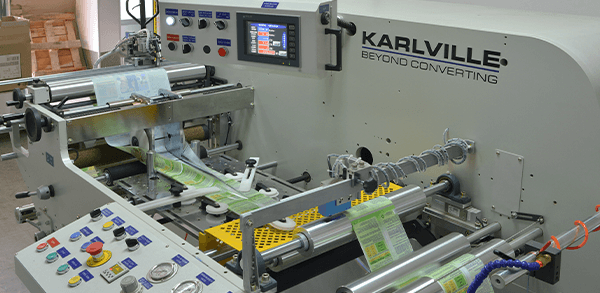

Shrink sleeve labels

On PVC and PET materials (the printing house has a specialized machine to make such labels)

In mold labels